Get Your All-Flo Pumps and Parts Now With FREE SHIPPING - Ends 1/31. SHOP NOW >

AODD Pumps for Paints and Coatings

Producing paints and coatings requires pumps that can keep pace with demanding formulas for abrasive pigments, thick resins, fast-moving solvents and batches that leave no room for contamination.

Built for Abrasion, Solvents and Color-Critical Production

Unlike many industries and AODD pump markets, coating lines must move fluids that actively attack pump components such as gritty solids that erode internals, solvent blends that stress elastomers and high viscosity bases that challenge flow consistency. Pumps used need to be able to handle:

- Abrasive pigments such as titanium dioxide and iron oxides.

- Solvent-borne formulations that demand chemical-resistant materials.

- Water-borne coatings that require fast cleanup and low residual carryover.

- Resins, binders and epoxies with variable viscosity and shear sensitivity.

- Additives and modifiers that may clog restrictive flow paths.

This combination makes the paints and coatings sector highly abrasive, highly chemical and highly cleanliness sensitive.

Reducing Wear Without Compromising Batch Quality

Wear and color contamination are major concerns in coating plants. When diaphragms wear prematurely, pigment slurries lose consistency, and a single leak can ruin a batch’s opacity or tint accuracy.

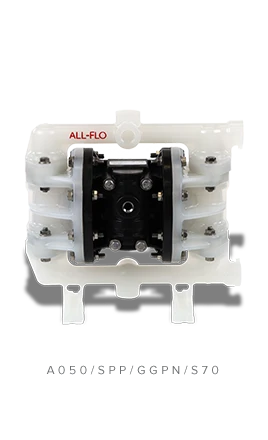

AODD pumps by Wilden® and All-Flo™ are designed for this environment and use materials that resist long-term abrasion.

For example, Dunn-Edwards Paints, a paints and coatings manufacturer, documented significant reduction to TiO₂-related diaphragm failures after switching to Wilden® Chem-Fuse™ technology. This was due to Chem-Fuse™ diaphragms being engineered to gold up against acids, caustics and other aggressive fluids, such as latex. These sane durability benefits apply directly to manufacturers handling abrasive pigments or running high-volume production, too.

Solvent Handling That Doesn't Slow You Down

Solvent-borne paints place heavy demand on pump internals and air systems. Selecting the proper pump configuration allows teams to:

- Handle aggressive solvents without damaging diaphragms by running solvent-borne coatings confidently and avoiding unexpected pump failures.

- Maintain steady, reliable flow during batch mixing, to ensure that there’s even movement of pigments and resins leading to more consistent, accurate batches.

- Switch between resin and solvent formulations with minimal delay for faster transitions that keep production timelines on track.

- Clean and flush pumps quickly during product changeovers for rapid removal of residual material reducing contamination risk.

- Adapt pumps to different chemistries with quick diaphragm swaps and adjustments that improve flexibility for processes running multiple lines.

Configured for Real Coatings Production

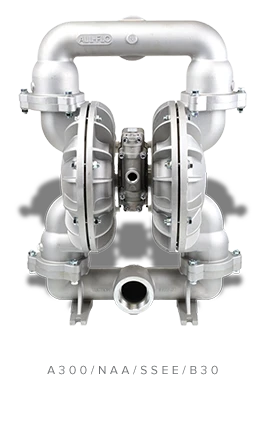

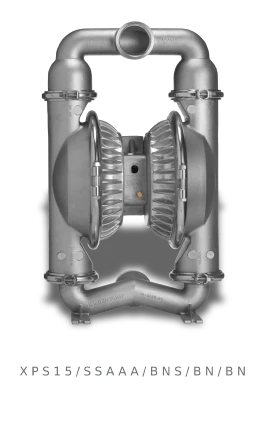

Coating teams need pumps that can reliably handle solvents, resins and abrasive pigments that make these products. That’s why recommended configurations emphasize bolted aluminum construction paired with abrasion-resistant diaphragms capable of withstanding repeated exposure to TiO₂ and high-solids formulations. These materials not only resist wear but also help maintain consistent flow needed for tint accuracy and batch uniformity.

Using standardized rebuild kits and genuine parts can simplify maintenance for teams that balance multiple product lines with frequent changeovers. Together, these design choices reduce downtime, extend pump life and support the demanding production schedules common in modern paint and coatings facilities.

Proven Pumping Performance for Paints, Coatings and Chemical Transfer

Many manufacturers have published measurable improvements after transitioning to PSG® technology.

One Wilden case study on Mastering the Art of Paint Production highlights how paint manufacturing is often slowed by inconsistent flow and pigment setting. By implementing pumps designed specifically for coating materials, manufacturers achieved more stable flow during dispersion and mixing, improving batch consistency and reducing rework.

Another case study on TiO₂ demonstrates how titanium dioxide’s extreme abrasiveness accelerates wear on pumps not built for heavy pigment handling. Facilities that switched to abrasion-resistant diaphragms and optimized material experienced longer service life, fewer diaphragm failures and more consistent pigment feed. This stability helped maintain opacity, color accuracy and batch uniformity.

Frequently Asked Questions About AODD Paints and Coatings Pumping

Paint and coatings plants move fluids with extreme abrasion, solvent aggression and color sensitivity. Pumps for this industry are explicitly selected for their ability to withstand TiO₂, maintain color purity and support rapid changeovers between formulations.

Pigments, especially titanium dioxide and iron oxides, act like fine sandpaper on internal components. Resins and fillers increase viscosity and shear-thinning, while solvents raise compatibility concerns. Pumps must be built around these specific wear patterns.

They offer the right balance of chemical compatibility and abrasion resistance for paints and coatings. PTFE handles aggressive solvents; Wil-Flex (Santoprene®) performs well with water-borne systems and abrasive slurries.

Consistent flow reduces pigment setting, and leak-free diaphragms prevent contamination that could alter opacity, gloss or color matches. The pump’s material choices and internal geometry directly influence batch consistency.

Yes, with the correct diaphragm changes and material selections. Many paint plants use pumps that share internal piston components, allowing the diaphragm to be swapped quickly between runs.

Find Your Pump

Just answer a few questions, and our Pump

Finder will guide you to the right solution!

PUMP FINDER