Get Your All-Flo Pumps and Parts Now With FREE SHIPPING - Ends 2/28. SHOP NOW >

Positive Displacement Technology: AODD

Air-Operated Double-Diaphragm (AODD) pump tech is a versatile and reliable positive displacement solution for handling aggressive, viscous or solid-laden fluids. The PSG® Store offers designs from Wilden® and All-Flo™ that deliver performance, energy efficiency and ease of maintenance.

AODD Pump Brands Available on the PSG® Store

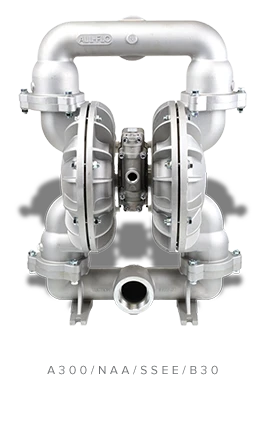

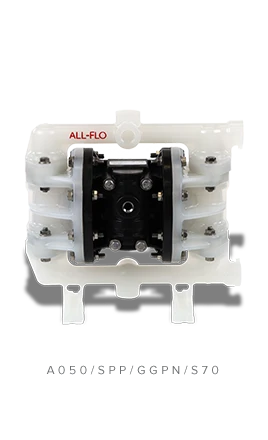

Since 1986, All-Flo™ has specialized in building straightforward, durable AODD pumps that are cost-effective to operate. With a variety of customizable options, All-Flo™ pumps provide reliable solutions across chemical, wastewater, food and general industrial markets.

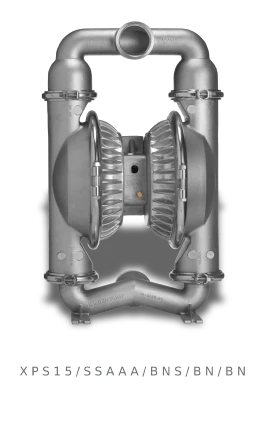

As the inventor of the AODD pump technology, Wilden® has been leading innovation for nearly 70 years. Known for safe, efficient fluid handling, Wilden® pumps are a top choice for your application, and with genuine parts and repair kits, maintaining performance is simple.

Positive Displacement Technology: AODD

Air-Operated Double-Diaphragm (AODD) pump tech is a versatile and reliable positive displacement solution for handling aggressive, viscous or solid-laden fluids. The PSG® Store offers designs from Wilden® and All-Flo™ that deliver performance, energy efficiency and ease of maintenance.

AODD Pump Brands Available on the PSG® Store

All-Flo™ Pumps

Since 1986, All-Flo™ has specialized in building straightforward, durable AODD pumps that are cost-effective to operate. With a variety of customizable options, All-Flo™ pumps provide reliable solutions across chemical, wastewater, food and general industrial markets.

Wilden® Pumps

As the inventor of the AODD pump technology, Wilden® has been leading innovation for nearly 70 years. Known for safe, efficient fluid handling, Wilden® pumps are a top choice for your application, and with genuine parts and repair kits, maintaining performance is simple.

Understanding AODD Pump Technology: Benefits and Applications

An Air-Operated Double-Diaphragm (AODD) pump is a type of positive-displacement pump powered by compressed air. Two diaphragms move back and forth, creating suction and discharge to transfer fluid. With their straightforward design and minimal moving parts, AODD pumps are easy to maintain and versatile enough to handle a wide range of fluids, from water-like liquids to abrasive slurries.

How Does AODD Pump Technology Work?

AODD pumps operate through a repeating cycle powered by compressed air. Air is directed into one chamber at a time, pushing one diaphragm inward to discharge fluid while the other diaphragm moves outward to draw fluid in. Ball or flap check valves open and close with each stroke to control one-way flow and prevent backflow. This alternating action creates a continuous, pulsing stream of liquid without the need for motors or complex drive systems. Because no electricity enters the fluid path, these pumps are particularly safe in chemical, sanitary and hazardous environments.

Benefits of AODD Pumps

The appeal of AODD technology comes from its reliability and safety. These pumps are self-priming and capable of running dry without damage, which minimizes downtime. Their ability to handle solids, viscous fluids and abrasive slurries makes them valuable in demanding operations. With no mechanical seals to leak, they reduce maintenance risks, and when repairs are needed, service is usually replacing diaphragms, valves or seals. For facilities that require compliance, sanitary and ATEX-certified designs are available through the PSG® Store.

Where AODD Pumps Are Used

Due to this flexibility, AODD pumps are widely adopted across various industries. In chemical processing, they move aggressive acids, caustics and solvents without contamination. In the food and beverage sector, FDA-compliant designs ensure the safe transfer of dairy, syrups and sauces while maintaining product integrity.

Municipalities and plants rely on them for water and wastewater treatment, handling sludge and dosing chemicals. In mining and construction, rugged builds manage abrasive slurries and dewatering tasks. Even in general industrial settings, AODD pumps are a go-to for drum transfers, coolant circulation and tank emptying.

Materials and Options

The PSG® Store offers AODD pumps in both metallic and non-metallic constructions to suit different applications. Aluminum and iron are cost-effective for general industry, while stainless steel is favored for its durability in chemical and sanitary environments. On the non-metallic side, polypropylene and PVDF offer broad chemical resistance, while conductive nylon is selected for the safe handling of flammable fluids.

Diaphragm choices add another layer of flexibility. Santoprene® balances durability and cost, PTFE offers maximum chemical compatibility and FKM withstands high temperatures and strong solvents. Connection styles, such as ANSI flanges, FNPT, BSPT and Tri-Clamp, further adapt the pumps to meet system requirements.

Maintenance and Repair

One reason AODD pumps are popular is their ease of upkeep. Routine service often involves replacing the diaphragm, cleaning the valve or swapping gaskets and seals. To simplify this, the PSG® Store carries wet end kits, air repair kits and factory-tested air valve assemblies. By using genuine parts, you can extend pump life, maintain optimal performance and minimize unplanned downtime across various applications, including chemical, sanitary and industrial settings.

Choosing the Right Pump

Selecting the best AODD pump starts with understanding the fluid being handled and the environment in which it will run. Corrosive or abrasive fluids require compatible materials such as PVDF or stainless steel. Sanitary or pharmaceutical processes may call for FDA-compliant construction. Flow rate, discharge pressure and suction lift should all align with system needs. Maintenance accessibility is another key factor, as designs that simplify diaphragm or valve replacement help reduce costs over time.

The Wilden® and All-Flo™ lines cover a broad range of requirements, while the Pump Finder tool on the PSG® Store makes it easy to match pump size, materials and series to specific processes.

Proven Results

PSG® has case studies highlighting how AODD pumps deliver measurable improvements in real-world operations. For example, at IndoChem, Wilden® Pro-Flo® SHIFT pumps reduce air consumption by thousands of SCFM and significantly decrease tank fill times. Hi-Tech Coatings International Limited saw a 75% increase in throughput after switching to Wilden® AODD models, which eliminated leaks and extended diaphragm life. In adhesive transfer, Chem-Fuse™ diaphragms simplified clean up and improved reliability, while mining operations have documented improved safety and uptime using Wilden® pumps in abrasive environments.

Frequently Asked Questions About AODD Pumps

Genuine diaphragms, repair kits, air valves and accessories are available through the PSG® Store. Ordering directly ensures you receive factory-tested parts specifically designed for your Wilden® or All-Flo™ pump.

No. AODD pumps are self-priming and can draw fluid into the system without the need for external priming equipment. They can also run dry for short periods without damage.

Yes. Most AODD pumps are designed to pass solids and slurries without clogging. Series like the Max-Pass® from All-Flo™ and solid-handling pumps from Wilden® are designed for applications such as sludge, mining slurry and wastewater treatment.

Yes. Both Wilden® and All-Flo™ manufacture sanitary diaphragm pumps built with FDA-compliant materials. These are widely used in bottling, canning, brewing and food or pharmaceutical production.

Yes. Because they are powered by compressed air rather than electricity, AODD pumps can safely operate in explosive or hazardous atmospheres. Many models are also available in conductive materials to reduce the risk of static discharge.

Genuine wet end kits typically include diaphragms, balls, seats and gaskets. Air repair kits contain air valves and pilot sleeve components. Both are engineered to match your specific pump model for quick and reliable service.

All pumps and parts purchased through the PSG® Store are shipped in accordance with our shipping policy. There, you can review delivery options, estimated timelines, and costs.

Yes. The PSG® Store accepts returns for eligible All-Flo™ and Wilden® pumps and parts within the timeframe outlined in our returns policy. Details on conditions and restocking fees are available online.

Warranty coverage, liability information, and customer rights are outlined in the Terms of Use and Terms and Conditions.

If you need help with an order, product recommendation, or shipment tracking, you can visit the Contact Us page to connect directly with PSG® Store experts.

Find Your Pump

Just answer a few questions, and our Pump

Finder will guide you to the right solution!

PUMP FINDER